Griffin High-Flow Hotend is an optional add-on designed for customers who print large bulky objects and need to print fast. It is also an excellent choice for printing thick vase mode style objects since the single walled objects are stronger.

This add-on is provided with 80W heater and a thermistor. The new addition is now delivered with a mounting CNC made bracket. This mounting protects and stabilizes the long heatblock during printing. As a result it provides high print quality as vibrations are minimized during accelerations

“IDEX” stands for independent dual extruder, where each extruder is capable of moving independently from each other. As a result, while the active extruder is printing, the second extruder is “parked” outside the printing area. Therefore, dual material printing made with IDEX technology comes out cleaner and with higher success ratios in comparison to other configurations as such the two print heads are installed side by side on the same carriage.

All our printers’ models are delivered with the electronic expansion board named Duex. This allows allocating a dedicated driver per each motor for both Z axis and X axis. As a result, Modix is now offering a full set of automated calibrations routines including:

– Bed tilting calibration

– Bed leveling

– Gantry alignment

– Z offset calibration

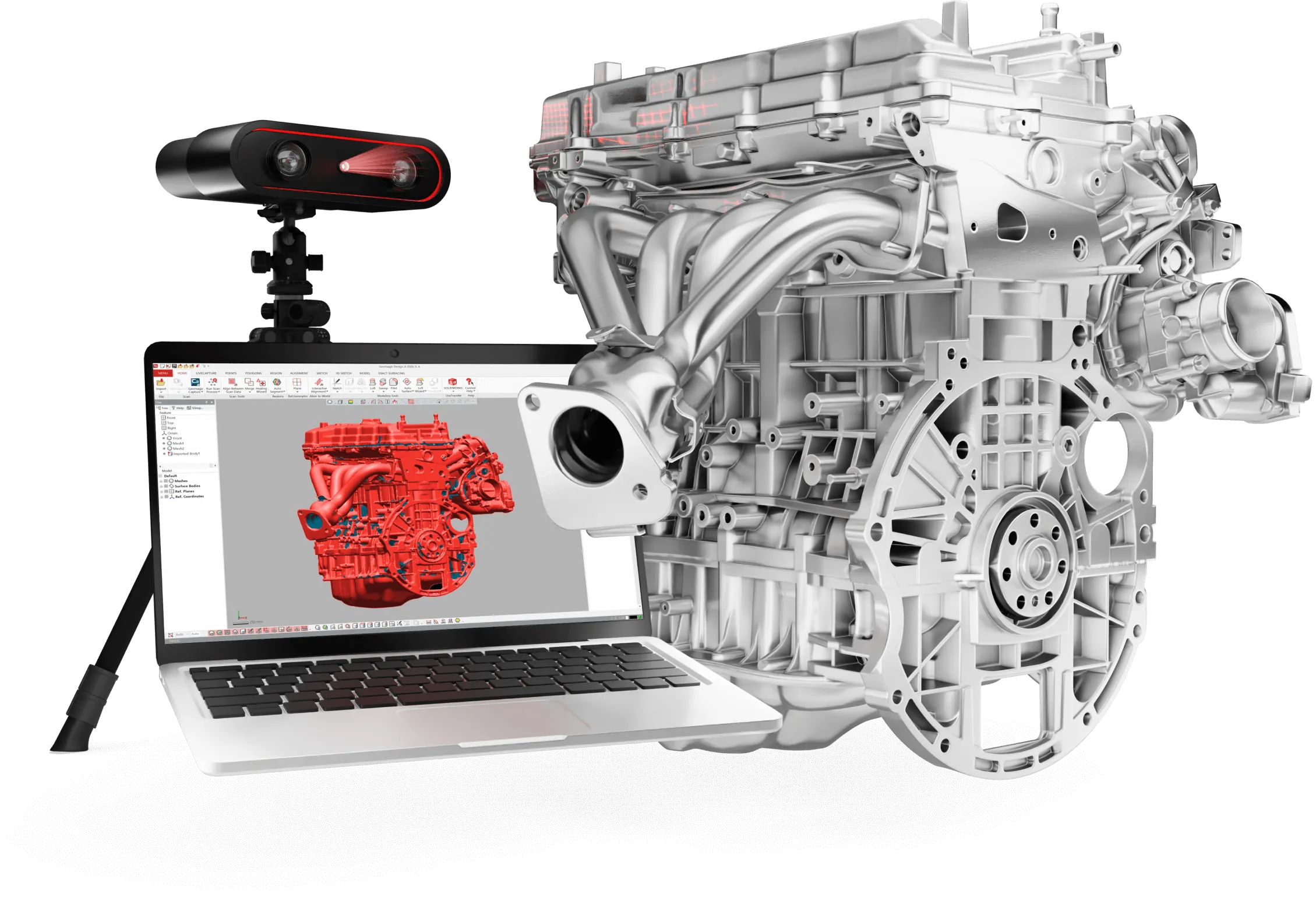

The Griffin print head family consists of 4 distinct configurations, all built on a shared design concept. Each print head is tailored to a specific printing profile and use case, providing users with the flexibility to optimize their workflow. Modix’s strength is its versatile offering, ensuring seamless adaptation to both current and future needs.

Independent Dual Extruder (IDEX) Option

The IDEX option allows for printing with support materials or dual colors, providing more design flexibility and the ability to create complex parts with ease.

HIWIN High-Precision Linear Rail Upgrade

An upgrade to HIWIN linear rails enhances the printer’s accuracy, resulting in smoother surfaces and better print quality.

Optional Enclosure

The optional enclosure improves print quality by maintaining a stable internal temperature within the print chamber, reducing the risk of warping and ensuring consistent results for large or temperature-sensitive prints.

| Parameter name | Value |

|---|---|

|

Technology

|

FDM |

|

Build Volume (XYZ)

|

1200 x 600 x 600 mm |

|

Accuracy

|

Z: ±0.2 mm + 1 layer |

|

Layer Thickness

|

0.1 ~ 1.2 mm |

|

Light Source

|

/ |

|

Nozzle Size

|

0.4 ~ 1.6 mm |

|

Printing Speed (Maximum)

|

251 mm/s (depending on nozzle size and layer thickness) |

|

Input Format

|

.stl, .obj, .3mf, .stp |

|

Material Catridge

|

/ |

|

Build Platform

|

removable (Magnetic Bed) (Option) |

|

Material

|

PLA, ABS, PETG, PC, PA, TPU, TPE, PVA, HIPS, ESD |

|

Printing Software

|

CF/GF reinforced filaments |