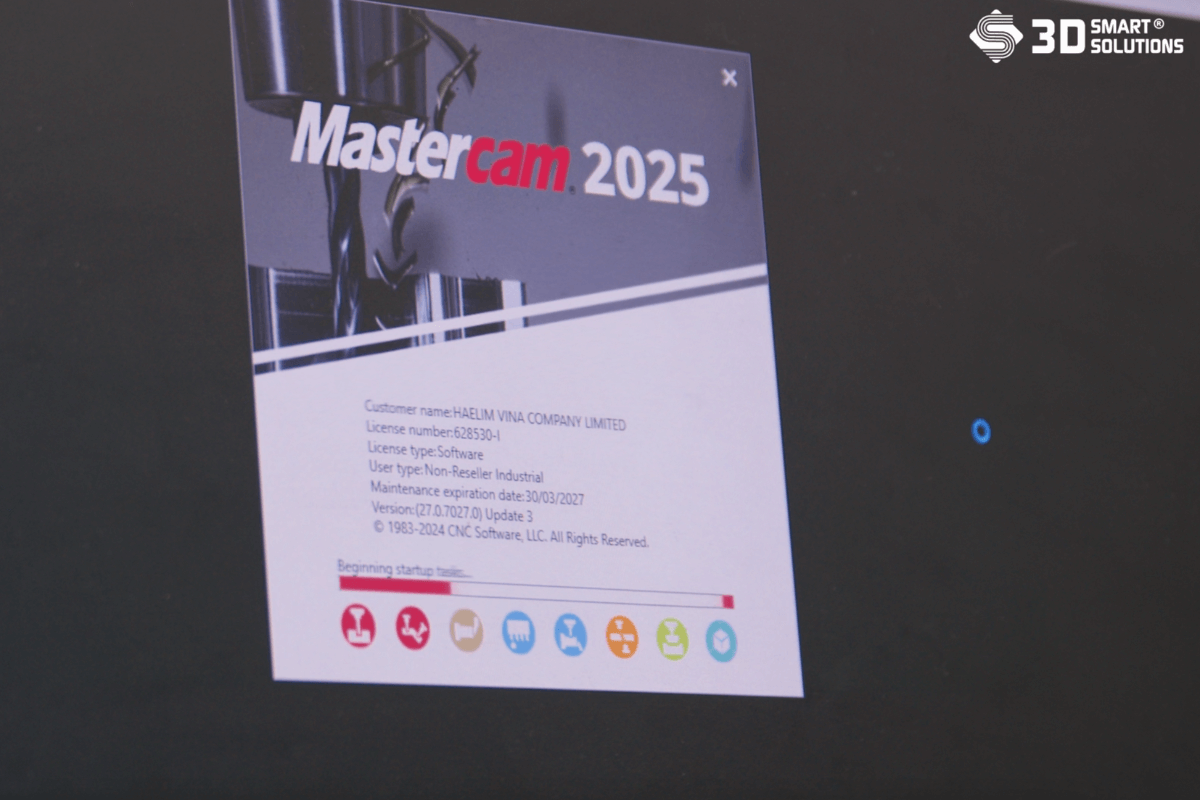

Haelim Vina, a key partner of Samsung Vietnam and a specialist in precision assembly components, electronics, and automation equipment, was in search of a high-accuracy solution to optimize its manufacturing process. To enhance its machining capabilities, Haelim Vina partnered with 3D Smart Solutions – the official Mastercam distributor in Vietnam. This collaboration went beyond software licensing, focusing on comprehensive training and technology transfer to help Haelim Vina fully leverage Mastercam’s potential. As a result, the company improved machining performance, product quality, and sustained its competitive edge in the industry.

Challenges for 3D Smart Solutions

Haelim Vina faced increasingly stringent machining demands, especially from Korean partners requiring complex, multi-surface parts with high standards for precision, surface finish, and flatness control. These challenges demanded an optimized machining process to ensure product quality while maintaining production speed.

Another significant challenge was enabling Haelim Vina’s technical team to quickly master Mastercam and unlock its full potential. Training needed to go beyond theory – it had to be practical, hands-on, and tailored to the company’s real-world manufacturing needs, ensuring optimal performance without disrupting ongoing operations.

To meet these high expectations, 3D Smart Solutions was tasked with not only delivering licensed software, but also providing a well-structured technology transfer roadmap. This approach empowered Haelim Vina to enhance its machining capabilities and streamline production in the shortest possible time.

A Breakthrough Solution by 3D Smart Solutions

To address Haelim Vina’s challenges, 3D Smart Solutions delivered a comprehensive solution designed to optimize machining processes and boost production efficiency. This solution was built around four key pillars: in-depth consulting, deployment of licensed Mastercam software, machining process optimization, and hands-on technical training.

With this integrated approach, Haelim Vina gained more than just powerful software – it acquired a streamlined, high-performance workflow and a skilled team capable of leveraging Mastercam to its fullest. This laid a strong foundation for sustainable growth and long-term competitive advantage.

Implementation Steps

Key Benefits of the Solution

Project Effectiveness

After implementing the Mastercam 2025 solution at Haelim Vina, the company has observed significant improvements in its manufacturing processes. The optimization of toolpaths has not only reduced machining time but also minimized errors and enhanced product quality. As a result, Haelim Vina is now able to meet the rigorous standards required by its South Korean partners and Samsung, further solidifying its reputation in the market.

Additionally, Haelim Vina’s technical team quickly became proficient with the technology through a comprehensive training program provided by 3D Smart Solutions. The adoption of Mastercam has not only boosted production efficiency but also helped reduce operational costs, decrease waste, and optimize resource utilization. These improvements have played a pivotal role in enhancing Haelim Vina’s competitive edge and expanding its collaboration opportunities within the machining industry.

Mastercam is not only a powerful tool for machining machine components but also offers optimized solutions for various other industries. In precision machining and mold making, the software enhances toolpath strategies, ensuring greater accuracy when machining complex parts. For automotive and aerospace manufacturing, Mastercam meets the high demands for durability, precision, and machining speed.

Moreover, Mastercam is also widely used in the medical device industry, where ultra-low tolerances are essential to meet stringent regulatory standards. In the machinery and automation sectors, programming with Mastercam ensures improved product stability and reliability. With its ability to streamline production processes, the software has become the go-to choice for companies looking to improve product quality and maximize operational efficiency.

Given the positive results, it is clear that Mastercam 2025, along with the support from 3D Smart Solutions, has delivered tangible value to Haelim Vina – boosting speed, precision, and technology mastery. However, the real impact is best understood through the eyes of those directly involved. We invite you to watch the video testimonial from Haelim Vina, where the production process has been truly transformed thanks to Mastercam and 3DS.

If your company is looking for authentic Mastercam software solutions, along with expert consulting, training, and technology transfer services, 3D Smart Solutions is the trusted partner you need. We are committed to providing the most effective solutions to help your business optimize production, improve quality, and maintain a sustainable competitive advantage.

“The collaboration with 3D Smart Solutions in implementing Mastercam software has brought clear results to our machining process at Haelim. Thanks to Mastercam 2025, we have reduced programming time, enhanced accuracy, and optimized both roughing and finishing processes. The 3DS team not only provided licensed software but also closely supported us in training and technology transfer, enabling our technicians to quickly and systematically master the technology.”

Partner with us to lead the way in technology innovation!

Contact 3D Smart Solutions to cooperate and develop together right now.

Other stories