Precision in sole molds changes everything – from product quality to manufacturing efficiency. Yet traditional methods are riddled with inaccuracies, time delays, and high costs. Framas chose not to settle for those limitations.

Partnering with 3D Smart Solutions, Framas adopted the OptimScan-3M 3D scanner to digitize sole molds with micron-level precision. Going a step further, the Formlabs Form 3L 3D printer was integrated into their workflow to enable rapid prototyping, immediate design validation, and fast iteration. Faster turnaround – zero deviation – superior performance.

This is more than just a solution – it’s a breakthrough. A transformation that empowers Framas to elevate its manufacturing process, reduce production costs, and lead the footwear industry with innovation.

Challenges Faced by 3DS

Framas needed more than a standard manufacturing workflow. They demanded speed, absolute precision, and uncompromising optimization. This wasn’t just a project – it was a challenge that required a revolution in sole mold manufacturing:

- Errors must be minimal: Sole molds must be accurate down to the micron. Any deviation can disrupt the entire production line.

- Speed is critical: Designing, testing, and producing must be accelerated without compromising quality. Every delay means wasted time and cost.

- Seamless technology integration: It wasn’t enough to introduce new technologies – 3D Smart Solutions had to ensure that 3D scanning and printing systems would integrate smoothly into Framas’s existing workflows without causing disruption.

These challenges demanded a solution that was not only powerful, but truly game-changing. And 3D Smart Solutions was ready to deliver.

A Breakthrough Solution by 3D Smart Solutions

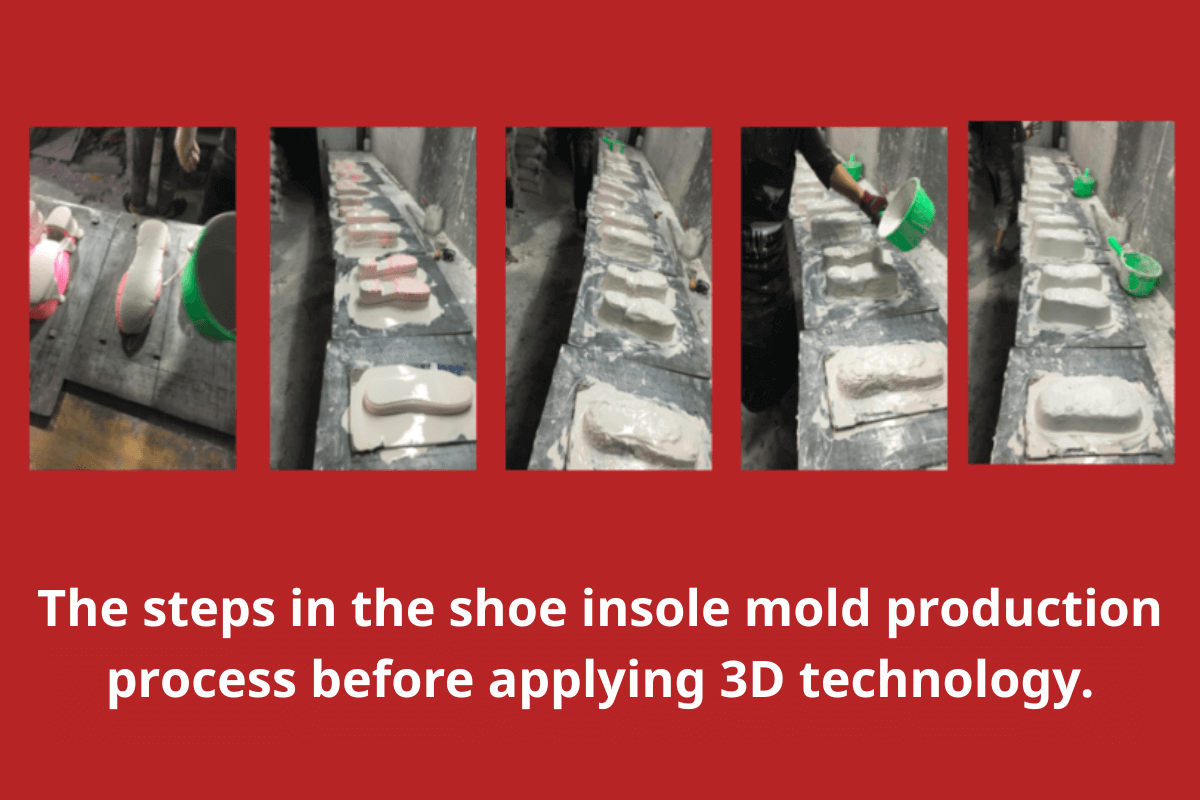

3D Smart Solutions deployed the OptimScan-3M 3D scanner to digitize sole molds with micron-level accuracy. All scanned data was directly compared to the original CAD model to ensure virtually zero deviation before moving into production.

- Accelerated workflow – faster time to market: by integrating 3D scanning and 3D printing technologies, Framas was able to rapidly prototype molds using the Formlabs Form 3L. This enabled instant testing, iteration, and validation – cutting mold development time from weeks to just days.

- Quality control from the start – risks eliminated early: 3D scanning data allowed Framas to detect even the slightest discrepancies from the design early in the process. This ensured timely corrections, preventing costly errors before mass production.

- Seamless integration – smooth technological transition: 3D Smart Solutions didn’t just supply the tools. They provided hands-on training and technical support, empowering the Framas team to quickly adopt and apply the new technologies without disrupting existing workflows.

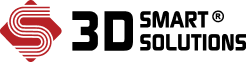

Implementation Steps

Key Benefits Delivered by 3D Smart Solutions

Project Effectiveness

After implementing 3D Smart Solutions’ technology, Framas optimized its entire shoe sole mold production process. Mold accuracy was elevated to the highest standard, with virtually zero deviation. The production timeline was dramatically reduced – from several weeks to just a few days – enabling faster project turnaround.

Beyond saving time and costs, Framas also strengthened its competitive edge by consistently delivering products that meet the highest quality standards. This wasn’t just a solution – it was a strategic leap that propelled Framas forward in the footwear manufacturing industry.

The true impact of a technology solution isn’t just in the specs – it’s in how it transforms real workflows. Check out this testimonial from Framas to see how 3D Smart Solutions helped streamline their production process and deliver real results.

With over 15 years of experience, 3D Smart Solutions is a pioneer in providing 3D scanning, 3D printing, and product design solutions for manufacturers. We don’t just bring cutting-edge technology, we help streamline workflows, boost efficiency, and reduce operational costs for our clients.

Looking to accelerate production, improve quality control, and lead your industry? Get in touch with 3D Smart Solutions today to discover the right 3D technology solution for your business.

“As a CAD Developer, I truly value our collaboration with 3D Smart Solutions. They not only provided precise 3D scanning and printing technologies, but also helped us streamline the entire mold inspection and adjustment workflow. As a result, we significantly reduced processing time, minimized errors, and saw a clear boost in design efficiency.”

Partner with us to lead the way in technology innovation!

Contact 3D Smart Solutions to cooperate and develop together right now.

Other stories