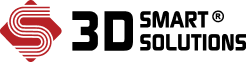

Can you imagine hundreds of shoes transforming into a majestic, contemporary Vietnamese dragon? It wasn’t just a bold idea but also a challenging project—where 3D technology from 3D Smart Solutions turned the impossible into reality. This article takes you behind the scenes of the inspiring journey to create the “Contemporary Vietnamese Dragon” model from 420 pairs of Biti’s shoes—a powerful statement of pride and innovation made in Vietnam.

Challenges for 3D Smart Solutions

To bring the unique vision of Biti’s and 8K Creative to life, 3D Smart Solutions had to overcome a series of tough challenges:

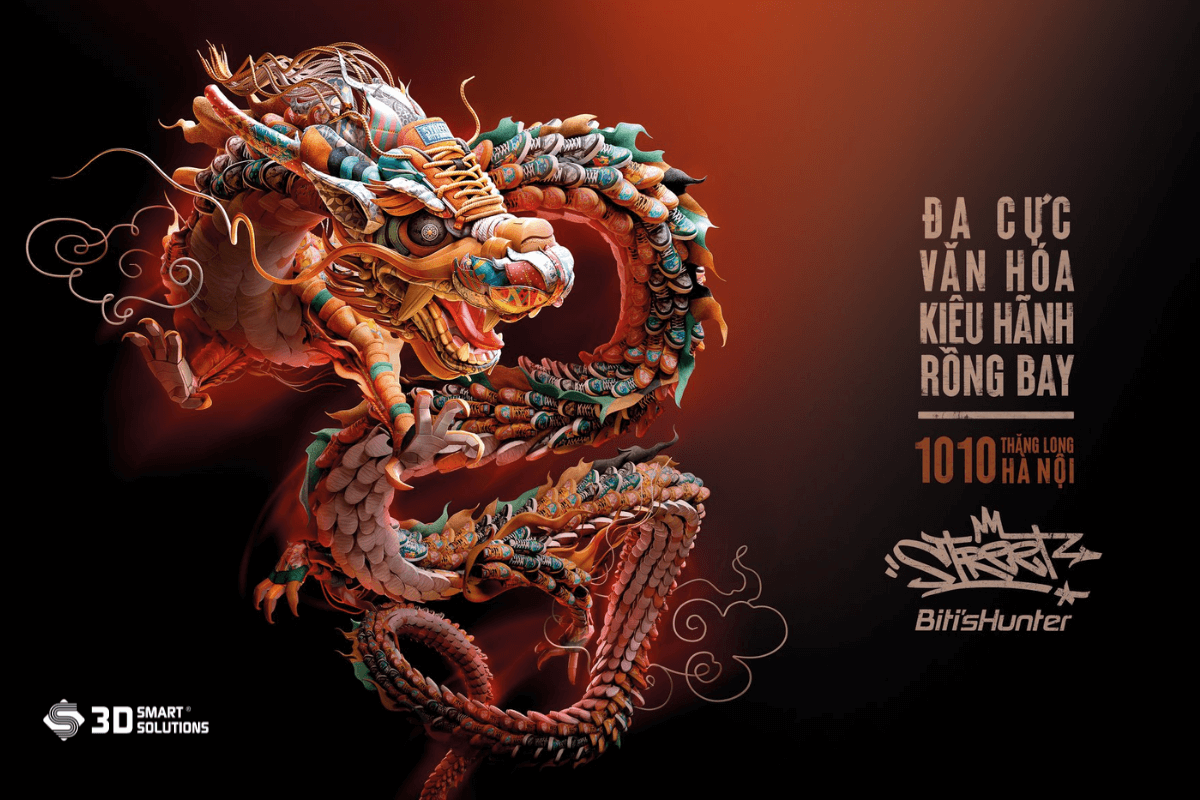

- Uniqueness and complexity: The dragon model demanded meticulous craftsmanship, fluidity, and the ability to capture the spirit of a sacred creature.

- Special materials: Creating the model from 420 pairs of Biti’s shoes was not just about the number—it was a challenge in handling, connecting, and maintaining the stability of such unconventional materials.

- Absolute precision: Every single detail, no matter how small, had to be perfectly recreated while staying true to the original design intent.

A Breakthrough Solution by 3DS

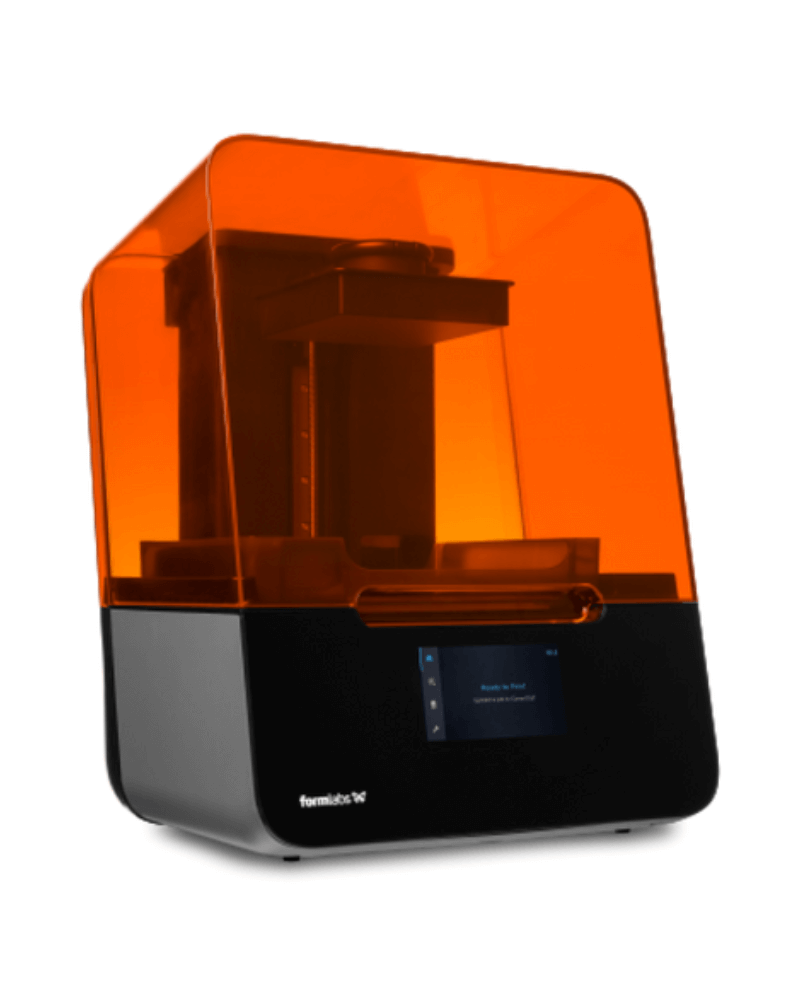

Faced with these challenges, 3D Smart Solutions introduced a breakthrough solution—combining cutting-edge technology with limitless creativity.

3D printing became the key. Instead of costly and time-consuming traditional methods, 3D printing made it possible to bring even the most complex designs to life with exceptional accuracy and unmatched speed.

Implementation Steps

Key Benefits of the Solution

Project Effectiveness

The “Contemporary Vietnamese Dragon” project is not only a technical success but also a powerful cultural milestone:

- Elevating the Brand: This project enabled Biti’s to deliver its “Proudly Made in Vietnam” message in an impressive and creative way, reaffirming its position as a beloved national brand.

- Showcasing Vietnamese Innovation: 3D Smart Solutions has demonstrated the technological capabilities and creativity of Vietnamese talent, paving the way for new directions in manufacturing and art.

- Creating a Symbol: The dragon model has become an emblem of harmony between tradition and modernity—uniting national pride with cutting-edge technology.

Don’t let your unique ideas remain only on paper. With 3D printing technology and proven expertise from landmark projects like Biti’s, 3D Smart Solutions is committed to delivering the most optimal solutions. Contact us today to unlock the unlimited potential of 3D technology!

Partner with us to lead the way in technology innovation!

Contact 3D Smart Solutions to cooperate and develop together right now.

Other stories